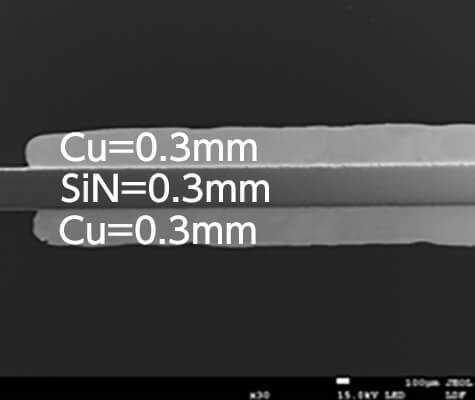

We developed insulated circuit board used in IGBT (Insulated Gate Bipolar Transister) , which is used as a high power frequency conversion device such as a hybrid car, a fuel cell car, an electric vehicle, a Shinkansen, CS-DBC). In recent years, when SiC replaced Si for semiconductor, SiN for insulating ceramics, and 1mm thick copper for circuit are used. We offer ceramic/copper joints by diffusion bonding.

Features of our products

- Improvement of thermal conductivity by absence of bonding layer

- Strong adhesion

- New construction method by proprietary development (S-DBC)

- correspond to SiN · AlN · Al2O3

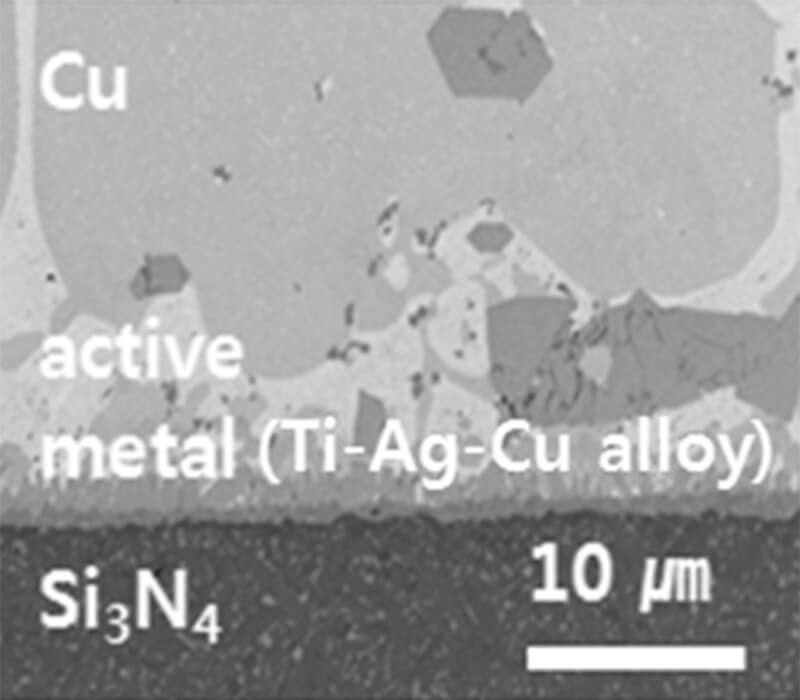

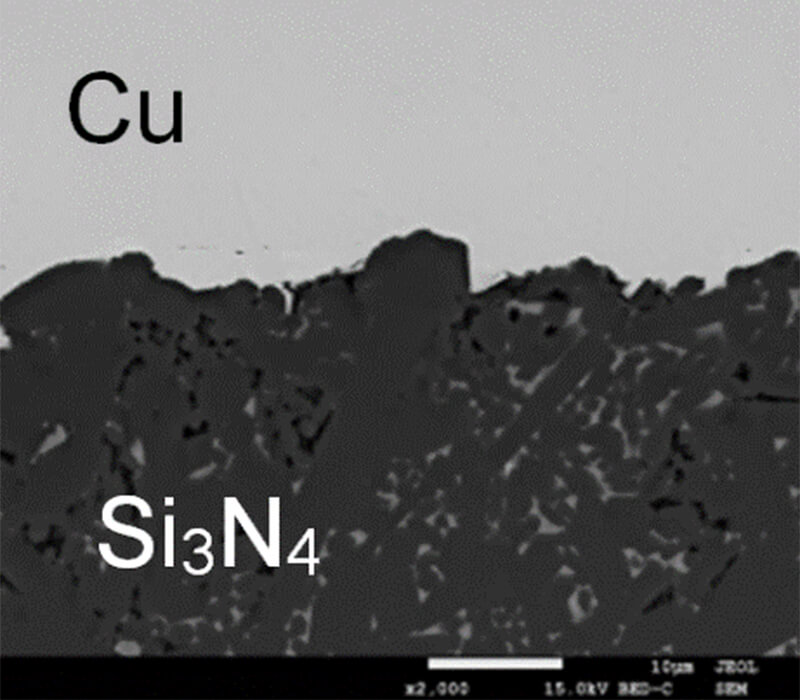

S-DBC method (Developed by FJ Composite)

S-DBC:Sputtering Diffusion Bonding Copper

Conventional method

S-DBC method

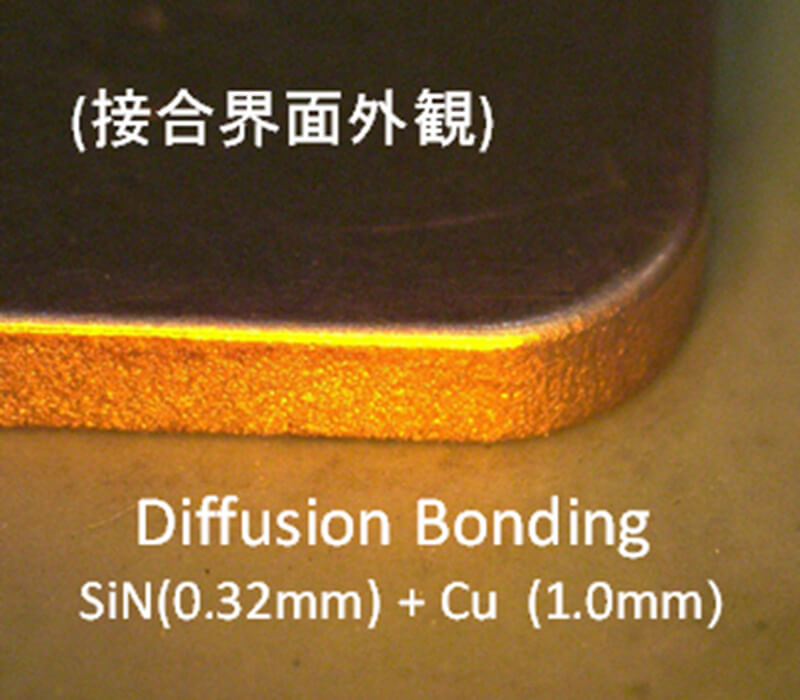

Diffusion Bonding

Joining strength evaluation of thermal diffusion bonding

(user evaluation result)

| AMB (other company’s product) | 98 N/4mm² |

| S-DBC (FJ Composite) | 106 N/4mm² (destruction of ceramic base material) |

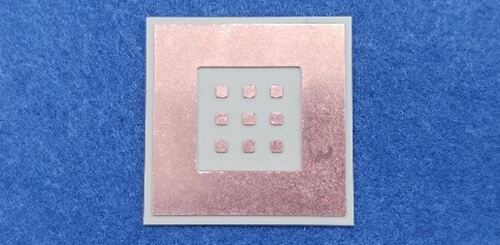

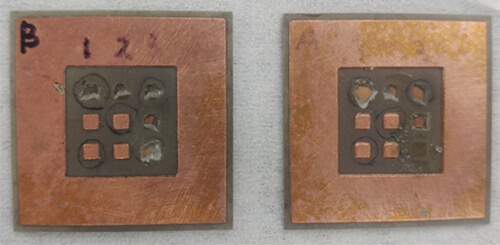

Before testing (Cu / SiN / Cu specimen)

After testing (bond strength> ceramic strength)

Heat cycle test

① High temperature operation Reliability test (-45 to 150 ° C / cycle, dwell time 20 min, @ each Temp)

-45 ~ 150 ° / 2000 times Test passed (User evaluation)

② Observation result of DBC circuit board bonding state

-40 to 250 ° / 3000 times Test passed (AIST evaluation result)

© 2023 | All content by FJ-Composites Japan