|

Cu-AlN AMB |

Advantages of DOWA’s substrates: |

Super - CMC |

|

|

|

|

|

|

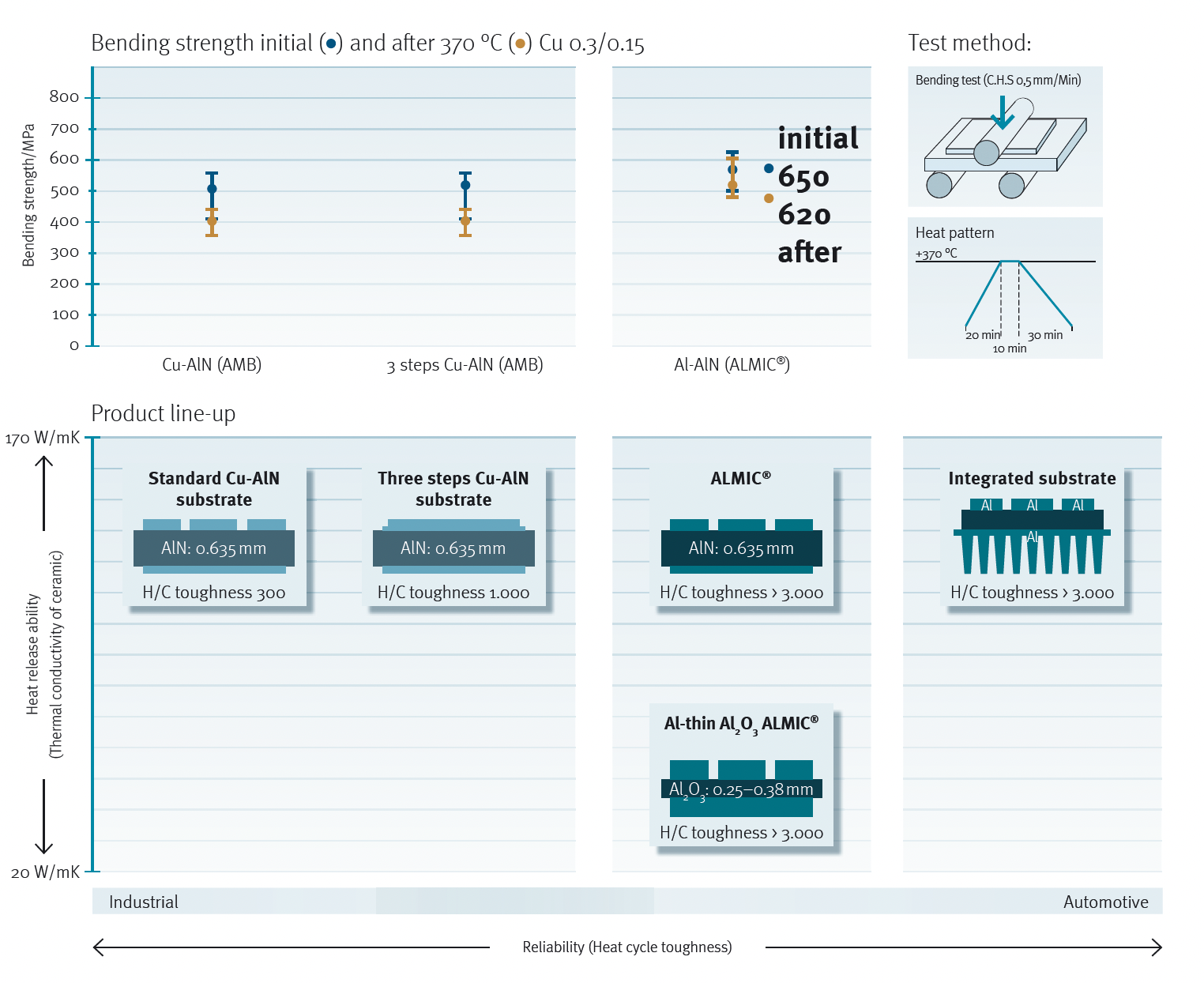

High ceramic bending strength |

|

|

X |

500 MPa @ 0.635 mm AlN |

|

|

|

650 MPa @ 0.635 mm AlN |

X |

|

|

|

|

|

X |

High thermal conductivity |

X |

|

|

AlN ceramic (Typ. 170 – 190 W/mK @ 20 °C) |

|

|

|

|

|

|

|

Very high partial discharge properties |

|

|

|

Typ. PD ≤ 10 pC @ 9kVrms; 0.635 mm AlN |

X |

|

|

|

|

|

|

Low substrate bow |

|

|

X |

Metallization during batch process |

|

|

|

|

|

|

|

Excellent bonding area |

|

|

X |

Cu-ceramic > 95% |

|

|

|

Al-ceramic > 97% |

X |

|

|

|

|

|

|

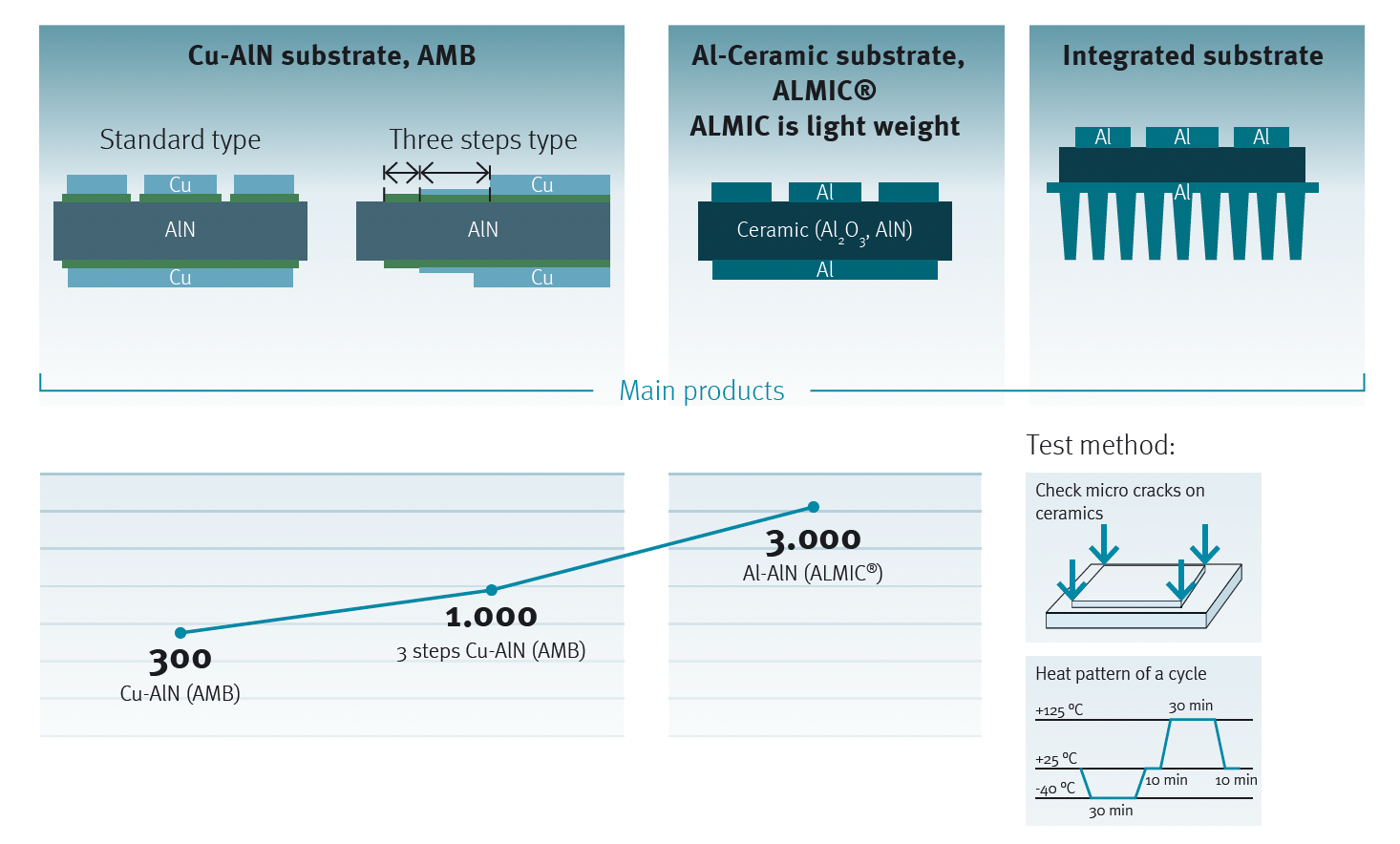

High heat cycle toughness |

|

|

X |

> 1.000 cycles @ -40/+125 °C |

|

|

|

> 3.000 cycles @ -40/+125 °C |

X |

|

|

|

|

|

|

Very good wire bonding |

|

|

|

Al-Al-wire bonding |

X |

|

|

|

|

|

|

Reduced weight |

|

|

|

Lighter than DCB- or AMB substrates |

X |